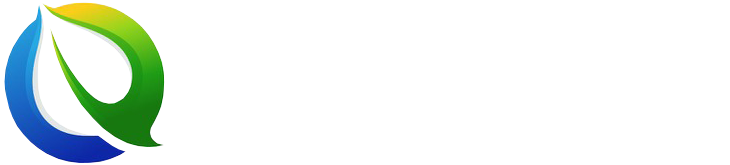

Next-Generation Biomass Processing

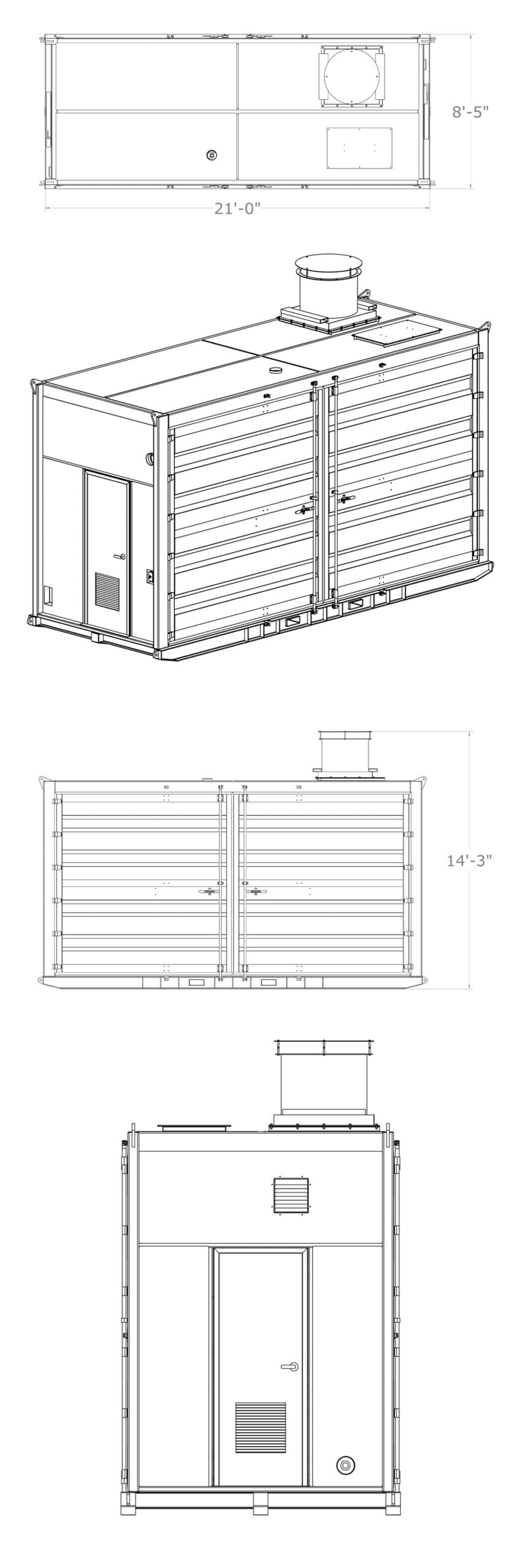

Qualterra’s patented biomass processing technology combines time-proven gasification and energy generating processes with modern, automated control systems to convert biomass into renewable energy and biochar. The Biomass Processing Unit (BPU) is housed in a rugged, modular shipping container and paired with various input and output modules, and is adaptable to accommodate a variety of biomass types and site requirements.